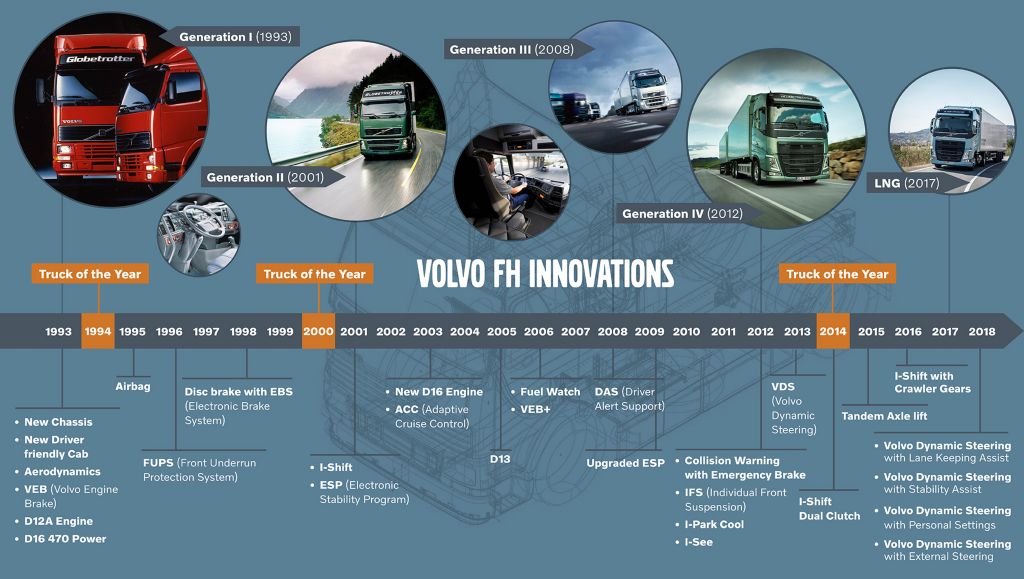

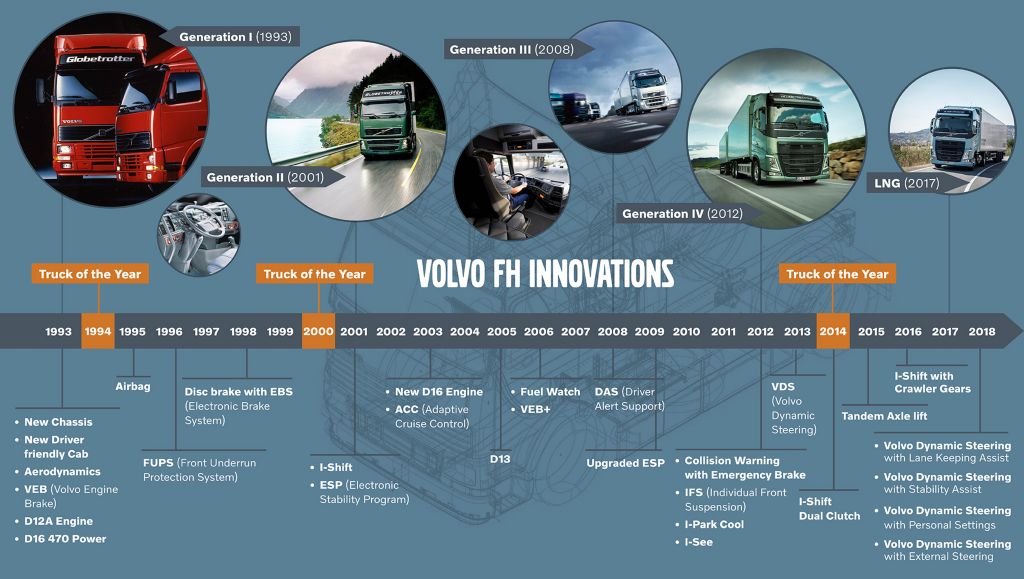

Volvo FH – 25 Years of Innovation

In 1993, Volvo Trucks introduced the world to the most the advanced truck yet: the Volvo FH.

With features like the D12A engine and Volvo Engine Brake, the technical specs impressed. But maybe even more impressive was the focus on the driver. The Volvo FH was – and continues to be – a driver’s dream. The new cabin acknowledged the situation for drivers. The truck is a workplace not only when driving, but also when resting or sleeping. Through extensive testing with more than 1,500 drivers and truck users, Volvo Trucks was able to construct a new cabin from the bottom up that created a whole new experience.

“We put the driver at the centre stage. And we still do,” says Mats Karlsson Lindh, Director Product Planning at Group Trucks Technology.

Today, the Volvo FH continues to advance the trucking experience. With features like the unique Volvo Dynamic Steering, that perfects the steering control and reduces driver strain injuries at the same time, Volvo Trucks keeps driving the progress forward.

The story behind the Volvo FH started in the mid 1980s. Volvo Trucks had a broad range of trucks for many markets, but there was a need for an improved process and common product program platform. With the FH, Volvo Trucks created a blueprint for future innovations. One of the key breakthroughs in the development was the new chassis. The dynamic design gave the engineers a common ground to keep developing and create features custom-fitted for every need.

“I have described this improvement of the industrial process as both a heart and brain transplantation for Volvo Trucks. It changed the way we work,” says Jan Johnsson who worked as project manager at the time.

As mentioned, the Volvo FH is a driver’s truck, but Volvo also acknowledges the business needs for the customers. This was as important at launch as it is today.

“The aerodynamic research we did on the design was unprecedented. That enabled lower fuel consumption for the customers,” says Mats Karlsson Lindh.

The chassis was also made with a clear business focus, with flexible solutions for different payloads. Today, Volvo Trucks leaves no stones unturned in the hunt for further fuel-cutting solutions for the customers. Updated I-shift software, tandem axle lift, I-park cool, Fuelwatch training for drivers and I-see predictive cruise control are just some of the recent innovations that improve the outcome for the customers.

Progress never stops. And the FH keeps improving. At Volvo Trucks the work continues.“We often start with a real customer problem. For example Volvo Dynamic Steering – one of the starting points was that we wanted to find a solution for reducing steering effort in roundabouts. During that research, we found so many new possibilities that something much more advanced evolved: the VDS as we know it today,” says Staffan Rödjedal.

Creativity and the nurturing of good ideas are two important parts of the process leading to successful innovations. Hard work is another one.

“You have to measure in the long, hard grind. Every feature has been tested and tried out for years before it works the way we want – and as well as our customers have come to expect.”